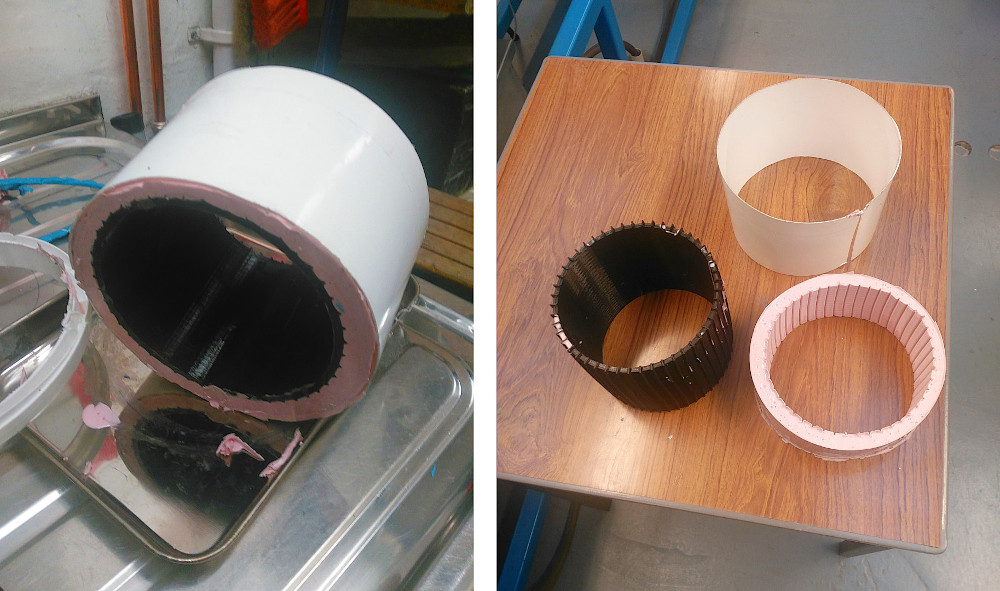

The six wheels have a design inspired by Perseverance wheels: before discussing the choices made for Mimas, it is worthy to briefly analyse the design made by JPL for their rovers. Machined out of a block of flight-grade aluminium and equipped with titanium spokes, each one of the Perseverance's six wheels is slightly larger in diameter and narrower than Curiosity's, with skins that are almost a millimetre thicker. They also feature new treads or grousers: In place of Curiosity's 24 chevron-pattern treads are 48 gently curved ones. For Mimas, steel was used to make a strong and flexible structure with inner suspensions made of bendy but strong steel strips. To obtain the 48 treads, the plan is to use a strong rubber (PU PX60) that will act as a tyre. In reality, rubber and plastic materials are not allowed for travels to Mars, since at very low temperatures, rubber acts as glass, becoming very brittle. Thanks to Lynn Chalmers, the technician for the polymers laboratory at Merchiston Campus, the manufacturing of the six wheels for Mimas can proceed smoothly!

- [Hours of work: 3h]

- [People involved: Giorgio, Lynn]