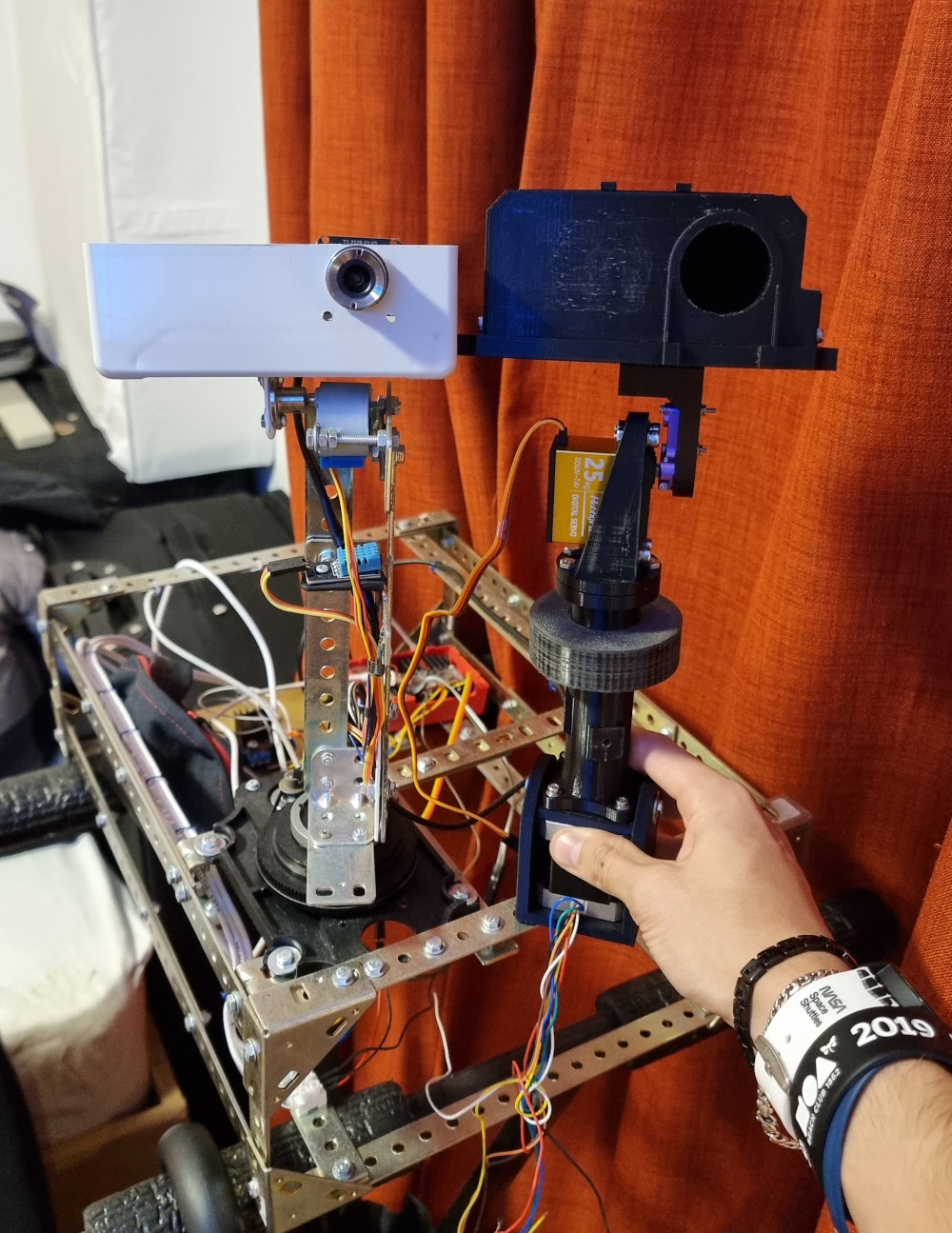

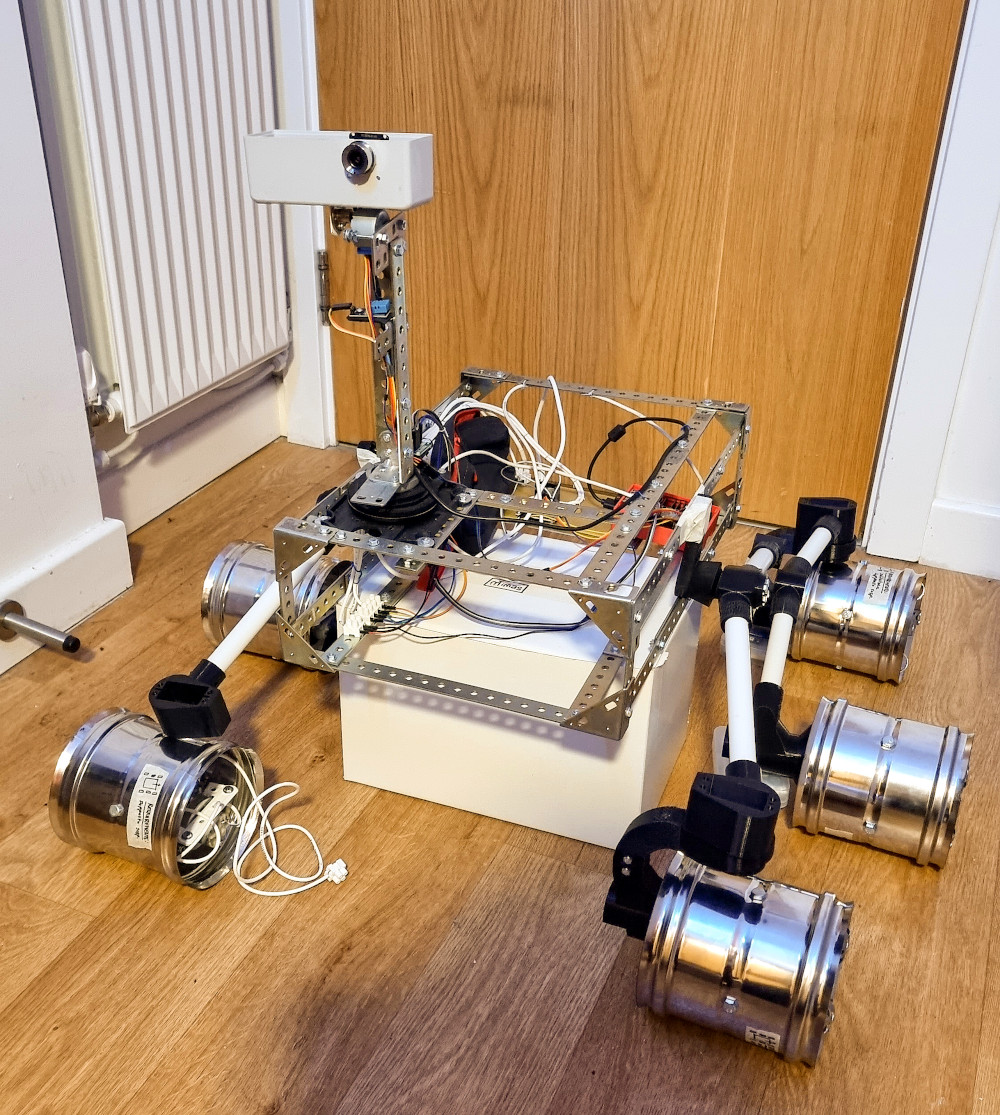

The control system used for Mast Tower v.2 is more or less the same as the one used for Mast Tower v.1. At the base of the structure there is a stepper motor controlled with steps and micro-steps: in Mast Tower v.1, a 4-cables stepper was used, connected to a gear reduction to overcome the lack of potential of the motor (quite damaged due to its second-hand state). Its torque was relatively low, not strong enough to move the heavy metal structure mounted on top of it. In Mast Tower v.2, an 8-cable stepper motor was chosen: the expectation was to take advantage of its heavy weight to add more structural stability to the whole tower.

Eventually, it turned out to not be a good option: there isn't much documentation about 8-cable steppers. Initially, the idea was to connect the coils that control the motor rotor, in series; however, a smooth rotational movement was not achieved in a reasonable amount of time.

This is the reason why a step back has been taken, substituting the 8-cable stepper with a twin of the 4-cable stepper motor used for Mast Tower V.1. Differently from the 1st twin, the 2nd twin is in perfect condition, so it was possible to ensure a great torque and precision even without a gear reduction.

In the end, there was no need to change anything in the code for the pan rotation, since the type of motor used is the same in Mast Tower v.1 and v.2. To ensure a precise tilt rotation, a high-precision servo has been assembled under the cameras housing. It is controlled with a few lines of code, resulting in an overall great upgrade from the first version of the Imager / Mast Tower!

- [Hours of work: 3h]

- [People involved: Giorgio]