Due to the end of the summer break, all components assembled in the past 2 months were disassembled and gently packed, ready for a long journey by car from Milan (Italy) to Edinburgh.

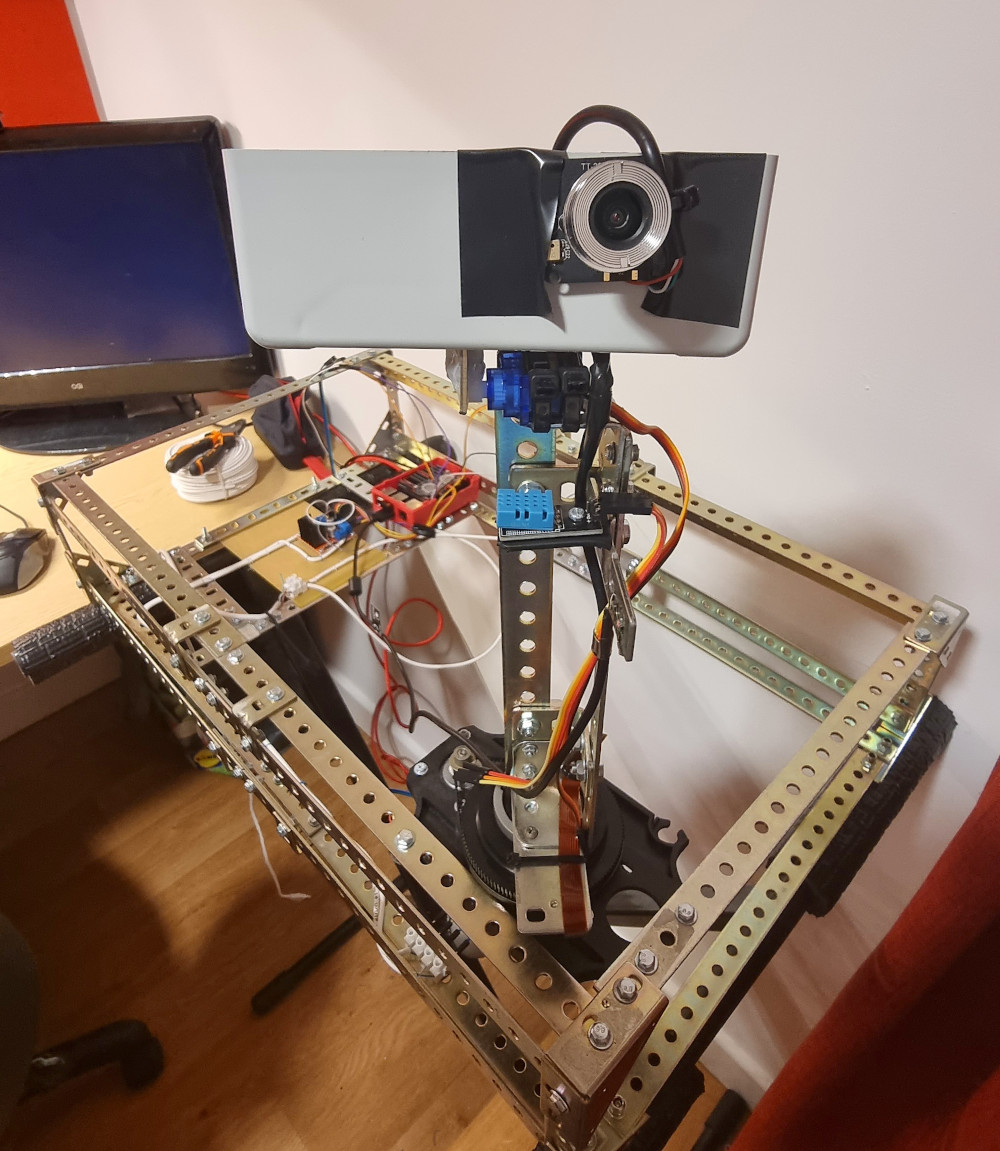

The overall list of innovations made for the Honours Project during the summer includes computer vision colour detection, computer vision free-path recognition, computer vision image stitching, a draft of the mast with its rotation mechanism, the WEB frame, six all-stainless-steel wheels, and a fully configured Raspberry Pi4. In addition, several additional components were packed for the trip: four high-torque servo motors, six high-torque DC motors, hundreds of connectors, jump wires, sensors, battery packs, motor drivers, nuts and bolts and many other equipment tools and consumables, for a total weight of ~50kg.

- [Hours of work: 1h]

- [People involved: Giorgio]