After several attempts, a stepper motor flange was installed on the structure, since previously the camera housing was attached to the motor only using a custom/adapted nut screwed tightly.

The new flange ensures structural rigidity and increases rotation precision. The code accuracy has been increased, as well as the algorithm used to process panoramic pictures.

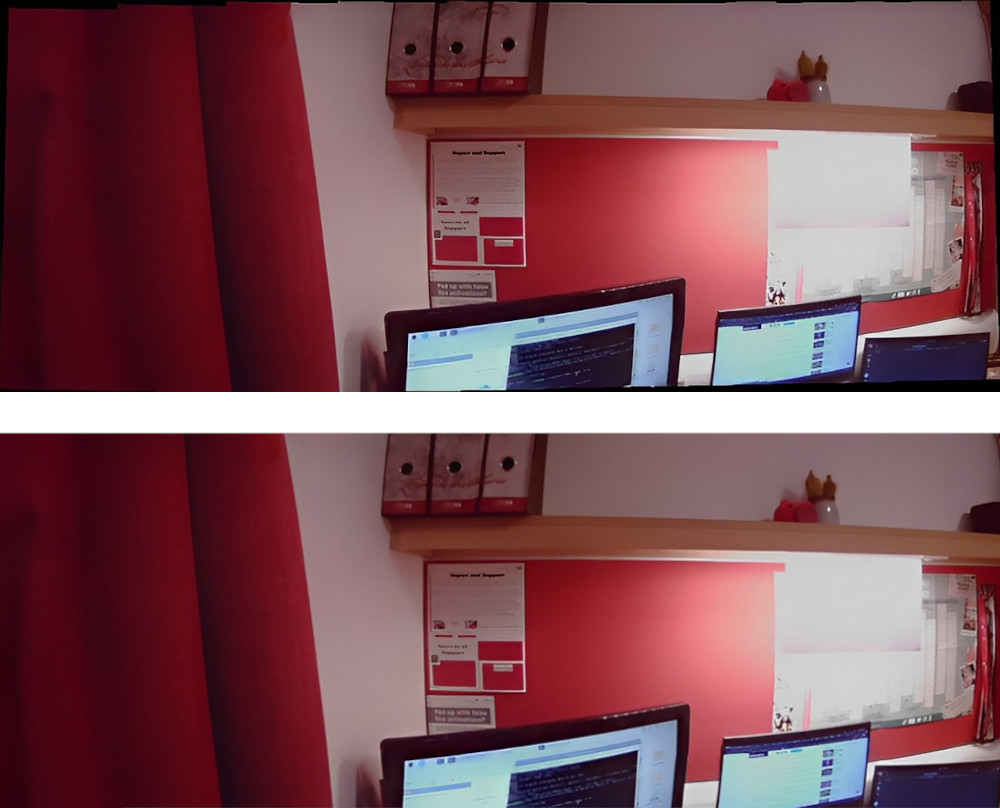

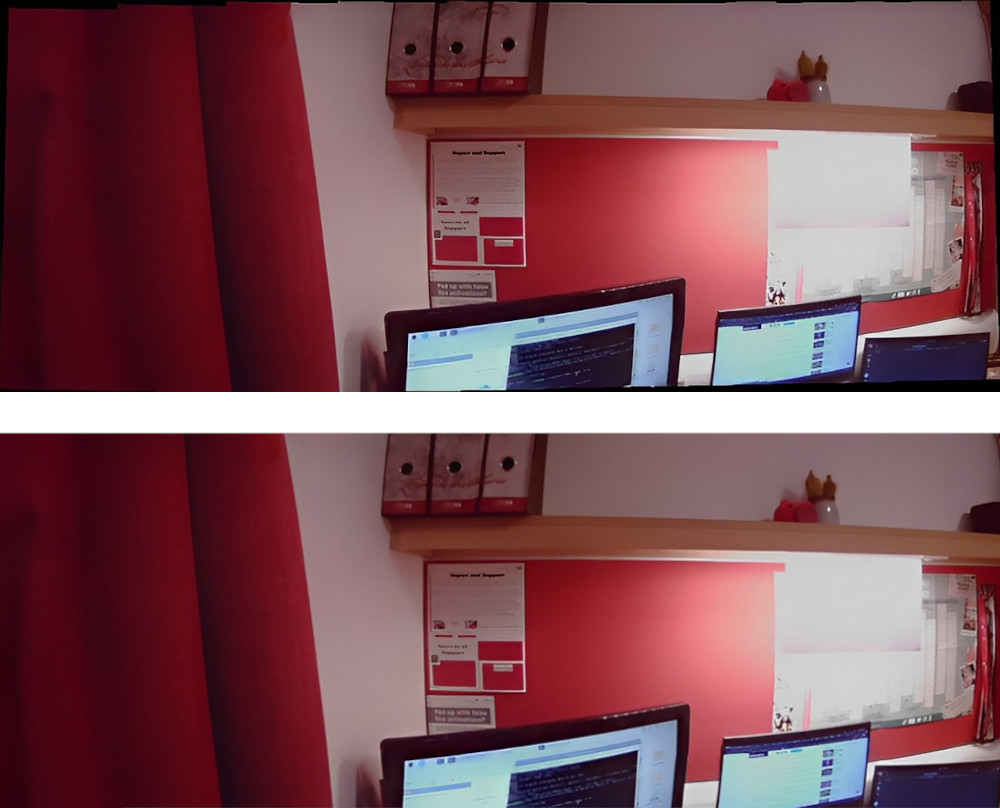

The main improvement concerns a post-process step to remove the lens distortion when taking a panoramic picture: even if the results obtained are good, there is still a lot of room for further improvements. The two images below show the differences between a non-processed panoramic picture (top) and a processed panoramic picture (bottom): the second one lost some details around the frame of the image, mainly on the upper and lower part.

- [Hours of work: 15h]

- [People involved: Giorgio]