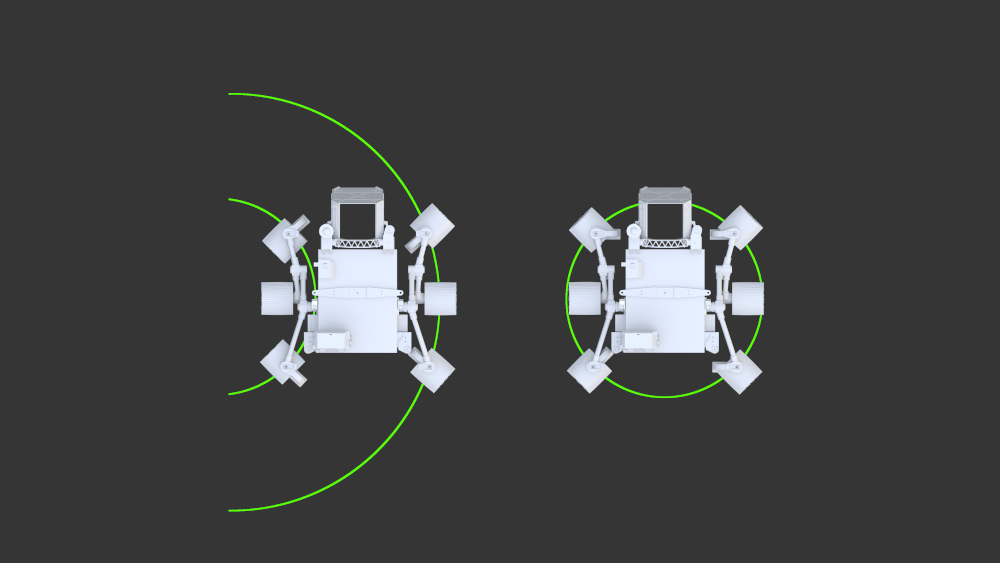

Taking advantage of a good discount, four webcams were purchased to reach the total final amount of cameras needed on board. They are all 720p HD cameras with USB connectors, ideal for computer vision tasks since the video stream is light enough for a Rasberry Pi. Full HD cameras (1080p) are also great, but one of the objectives of this project is to make the system as light as possible. Anyway, the four webcams will be added to the already existing three cameras to get a total of seven onboard cameras that will be used for the following purposes: 1x MasterCam (on the Mast), 2x NavCam (Navigation Cameras - on the Mast), 1x HazCam (Hazard Camera - rear of the rover), 2x SurCam (Surrounding Camera - LHS and RHS of the rover).

- [Hours of work: -]

- [People involved: Giorgio]